More efficient & ecological polyester dyeing

Outstanding qualities:

- Reduces the dyeing time of polyester with dispersed dyestuffs by ca. 35%

- Saves at least 30% of energy and water

- Helps to lower CO2 emissions by 30% during dyeing process

- Reduces manufacturing (wet processing) costs by 30%

- Top-performance polyester dyeing quality: color fastness, levelness and reproducibility

Added value:

- Winner technology of the Swiss Economic Environmental Award 2019

- Increased reproducibility (right-first-time) resulting in less rejects and waste

- Perfect color levelness for all types of dispersed dyes, also for critical shades

- Easily integration into current processes, as no adjustment of the dyestuff recipe is needed

- Only the replacement of the levelling and disperse agent is required

Wide-ranging applications:

- High flexibility, suitable for all standard polyester dyeing machines

- Applicable on wovens, knits and yarns

OEKO-TEX suited

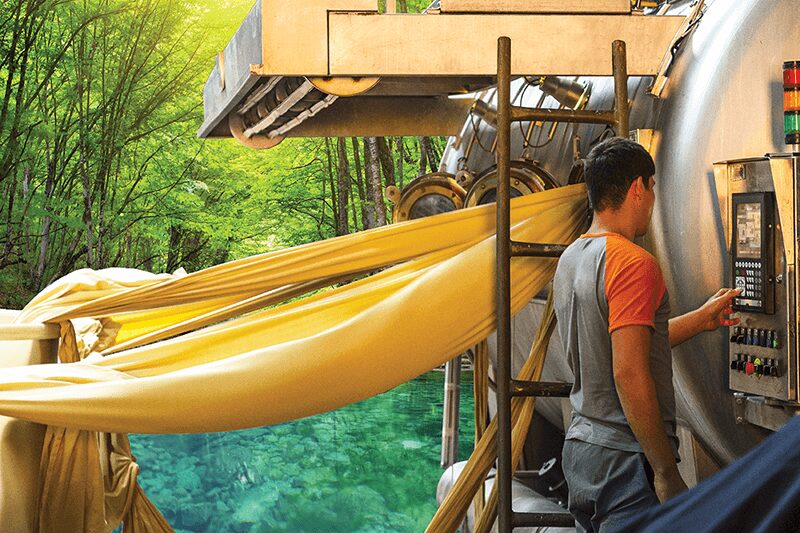

HeiQ Clean Tech™…

… is a family of innovative technologies designed to deliver sustainable, economical and ecological discontinuous piece and yarn dyeing for polyester.

This innovative HeiQ Clean Tech™ technology is eco-friendly and efficient, with time, water and energy savings of 30-40%. It enables a faster polyester dyeing process with

dispersed dyes as well as optimizing the textile product quality.

Behind the innovation

Polyester “swells” with temperature. The glass transition temperature of polyester (polyethylene terephthalate/PET) in an aqueous system is at ca. 85°C. At 130 to 135°C the capacity of the fiber to absorb the dyestuff achieves a maximum i.e. the fiber is fully “open” and the dyestuff can enter deeply.

Normal dyeing:

Dyestuff starts to adhere to the fiber surface at ca. 70°C. With heating, dyestuff moves into the fiber with increasing speed depending on the temperature rise. To avoid issues like unlevelness, dye jets are typically heated up slowly.

Dyeing with HeiQ Clean Tech™:

The auxiliary system puts the dyestuff in a “thermo-responsive box” which is closed at lower temperatures and prevents early striking of the dyestuff. The dyestuff is gradually released from the box at temperatures above 110°C and evenly distributed in the dyebath and on the fiber, and can migrate into the fiber.

Discover more about this technology!

Unlock the power of Ingredient Branding with HeiQ

Check out our exciting Marketing Ideas package or contact marketing@heiq.com

Ingredient Branding with HeiQ

Check out our exciting Marketing Ideas package or contact marketing@heiq.com